Pittsburgh Additive Manufacturing: Strong, Smart & Skilled

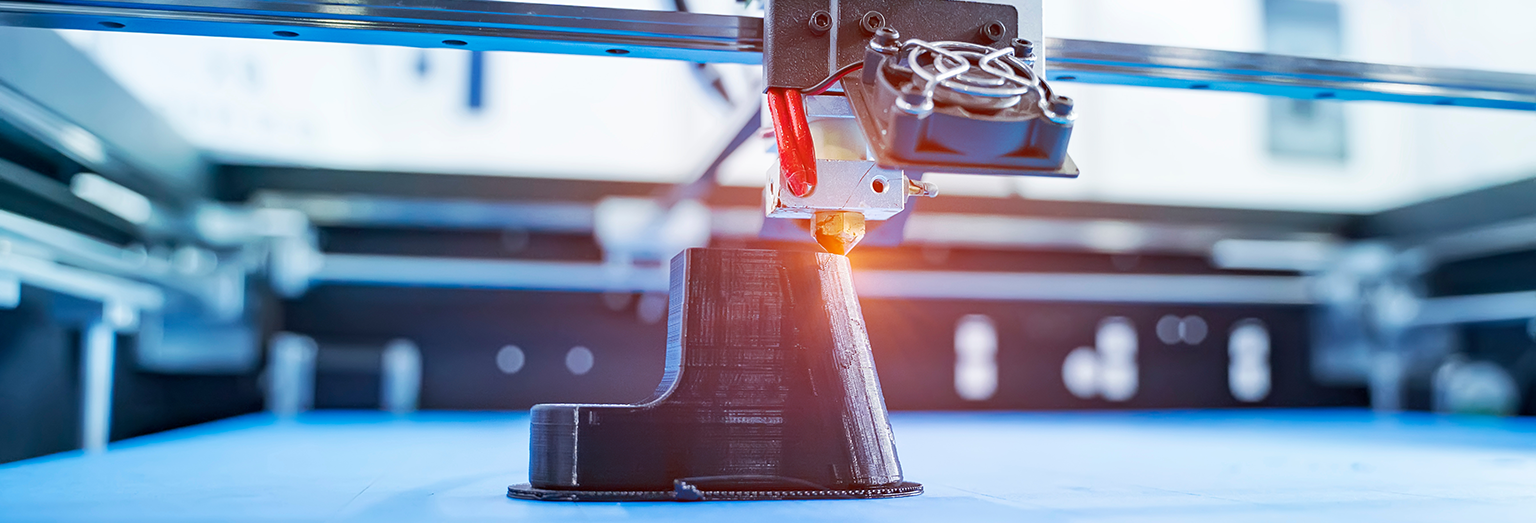

Pittsburgh is the perfect fit for the additive manufacturing industry. This region has a long-standing history as an American industrial hub. As a leader in advanced and traditional manufacturing, Pittsburgh provides a solid foundation for adopting and integrating these additive manufacturing technologies. The region’s strengths in R&D, tech and innovation uniquely position it to shape the future of this industry.

The additive manufacturing ecosystem is actively expanding across our 10-county region. The Pittsburgh region is strong in the four component industries of additive manufacturing: hardware, software, materials and services.

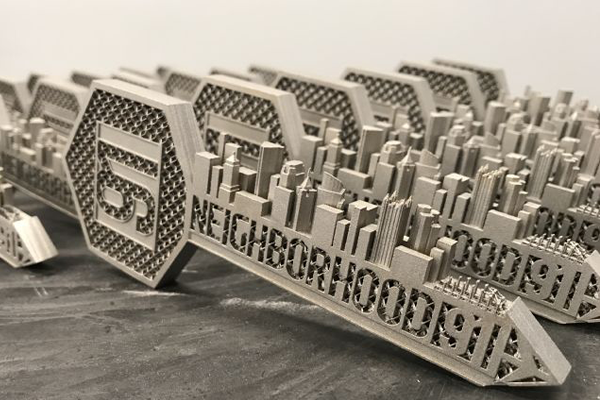

A great example of our thriving additive ecosystem is Neighborhood 91. Located on Pittsburgh International Airport property, Neighborhood 91 co-locates all parts of the additive manufacturing process. A first-of-its-kind additive manufacturing production campus, this central property focuses on making the industry more efficient.

As a growing hub for American additive manufacturing, Pittsburgh is home to industry leaders and innovators, including ExOne and Metal Powder Works. From rapid prototyping and on-demand production to advancements in 3D printing technology, high-performance additive manufacturing companies across the region are setting the tone for this industry in the US.

Pittsburgh’s highly skilled talent plays no small role in this. Additive manufacturing laboratories exist at two leading institutions in the region, Carnegie Mellon University and the University of Pittsburgh, ensuring Pittsburgh’s workforce is well-trained on in-demand manufacturing processes like stereolithography and injection molding. Read on to learn how the Pittsburgh region is at the forefront of cutting-edge additive manufacturing.

“You’ve got great universities like Pitt and CMU and they invent things, and now we’ve got Mill 19 and Hazelwood Green, which is like the development flavor. Between Hazelwood Green and Neighborhood 91, that’s 400 acres of development and production capability. And I would be surprised if that’s matched anywhere in North America.”

FOUNDER, THE BARNES GLOBAL ADVISORS

Ecosystem Support

Neighborhood 91

Neighborhood 91 is the first end-to-end additive manufacturing production campus in the world. It is located at the Pittsburgh International Airport’s 195-acre Pittsburgh Airport Innovation Campus. The campus brings together the AM/3D printing supply chain, streamlining workflows into one efficient production system.

America Makes

America Makes National Additive Manufacturing Innovation Institute in Youngstown, Ohio, is a short drive from Pittsburgh. The institute is one of the nation’s leading public-private partnerships for additive manufacturing technology, advancements and education. It works to improve the competitiveness of American 3D printing companies and startups globally.

Carnegie Mellon University’s Next Manufacturing Center

The Next Manufacturing Center at Carnegie Mellon University is a world-leading research center for manufacturing services. The center leverages the university’s engineering and data science expertise and state-of-the-art equipment in the additive manufacturing laboratories on campus and at Mill 19 in Hazelwood Green.

Pitt’s Ansys Additive Manufacturing Research Lab (AMRL)

The AMRL is a partnership between Ansys and the University of Pittsburgh. This research lab is equipped with some of the most advanced additive manufacturing devices, like Stratasys and ExOne 3D printing systems. This technology utilizes metals, alloys and polymers to print components for most industries, including healthcare, defense and consumer products.

TALENT

- Two of the best additive manufacturing degree programs in the U.S. are in the region or nearby

- Carnegie Mellon University’s Master of Science in Additive Manufacturing

- Westmoreland County Community College’s Advanced Technology Center

- At the Advanced Technology Center, students can receive an associate degree, diploma or certificate in Additive Manufacturing. Students get hands-on experience operating 3D printers capable of producing various types of precision polymer and metal parts.

- CCAC’s Center for Education, Innovation & Training

- The Community College of Allegheny County recently opened its new center for the future. This state-of-the-art center focuses on skills training for fast-growing occupations, including those in the additive manufacturing industry.

Pittsburgh Additive Manufacturing Companies – Success Stories

6K Additive

6K Additive is a sustainable producer of metal powder including nickel, titanium, copper and hard-to-manufacture refractory materials. Its proprietary UniMelt microwave plasma technology utilizes materials like CNC scrap and turns it into premium powder. 6K delivers a high-quality, low-cost and sustainable approach to powder and metal additive manufacturing.

ExOne

This Irwin-based firm delivers powerful, industrial 3D printer systems as well as end-use designs for consumer goods and 3D printing services for sectors like automotive, R&D and decorative art. ExOne has even made sustainable serial production a reality for the luxury automotive brand BMW thanks to their 3D printing solutions. ExOne is a subsidiary of Desktop Metal.

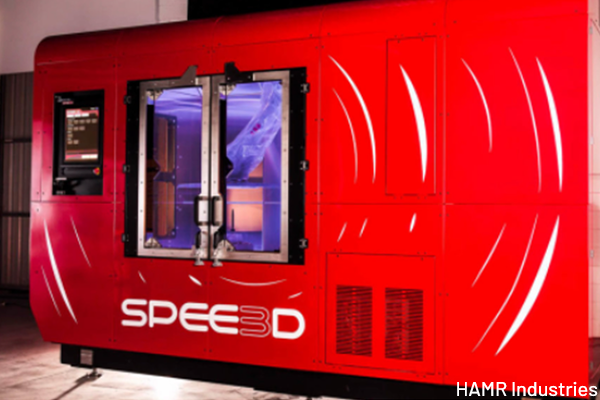

HAMR Industries

HAMR develops additive manufacturing solutions for material components functioning in harsh and extreme environments. Its industry focus includes aerospace, hypersonics, space and nuclear. Located at Neighborhood 91, HAMR’s new WarpSPEE3D system is a large-format cold spray additive manufacturing (CSAM) unit. This unit can produce full-scale parts in a rapid and affordable manner.

Metal Powder Works

Metal Powder Works creates metal and polymer powder used in additive manufacturing. The company does so in a cleaner, more sustainable way through its patented DirectPowder™ process. This process solves many safety issues surrounding shipping and storing metal powders. Metal Powder Works is also a tenant at Neighborhood 91.

thefutureofjewelry

THEFUTUREOFJEWELRY is a direct-to-consumer custom jewelry company whose cutting-edge software seamlessly merges user-driven customization with on-demand manufacturing. Each piece of jewelry is 3D printed in wax resin and casted in precious metal, ensuring a perfect fit with over 100 ring sizes available.

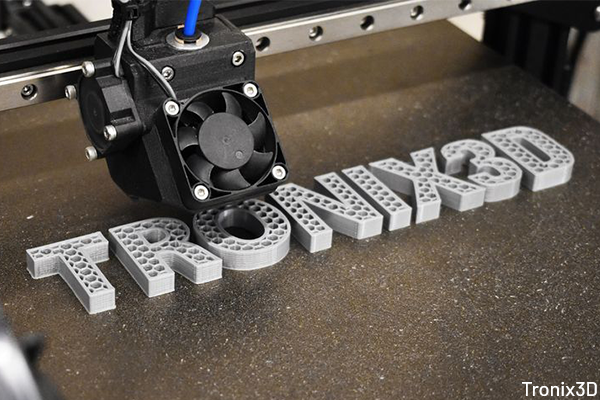

Tronix3D

Tronix3D is a contract-based additive manufacturer for the robotics, energy, automotive, medical devices and defense industries. The company specializes in low-volume production and prototype parts. Tronix3D is also a leading provider of mechanical design and consulting services for additive manufacturing.

Contact Us